Injection Moulding

Plastic Injection Moulding

TopWell is recognised as one of China’s leading Plastic Injection Moulders. We have 20 years of rich experience building plastic injection moulds and providing end-to-end tooling solutions for various range of industries. We have advanced and sophisticated high precision machines, which enables us to make close tolerance injection moulds under competitive lead-times. We Manufacture Plastic Moulds and supply Moulded Components of high standard quality which are exported all around the world. To serve this purpose we have up to date injection moulding facilities along with required tool manufacturing set up.

Plastic Mold Manufacturer and Assembling

Computer Numerical Control Machining & Computer Aided Manufacturing.

After receiving the checked program files and printed copy from CNC Programming Section, get the assigned Steel, Copper and Mold Base from the Warehouse; Milling Section or Grounding Section then will start the proper processing.

After mounting the Steel; Copper or Mold Base onto the CNC Machining Centre or CNC Machine, calibrate the related co-ordinates, seting the Datum.

Loading the related program to the machine and double check all the information, such as Mold Number; Steel Insert Number or Copper Electrode Number.

This is to be sure that all the parts and accessories in house are having their own marking numbers and all of them are traceable.

After machining is complete, Parts and Accessories will be sent to QC Department to inspect the critical dimensions before being released to EDM and / or Wire Cutting Sections for further processing.

Electrode Discharge Machining

When QC inspectors complete the dimensions check, electrodes will be sent to Polishing Section to polish away the surfaces to their requirements then released to the EDM Section.

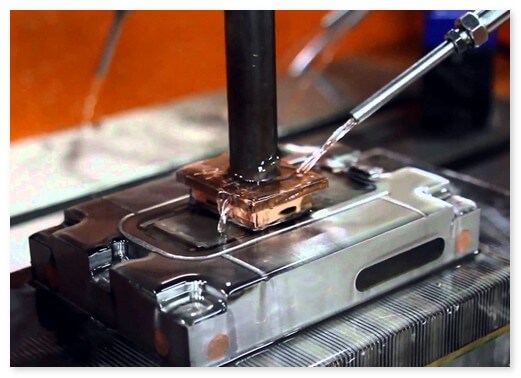

EDM Technicians will check the number of the Work Piece (Steel Insert; Beryllium Copper and others), the Copper Electrodes , Set up Data Sheet and the EDM program number, to ensure all these items belong to the same job order.

Mount the work piece onto the EDM Machine and calibrate and reset the Datum, input the EDM program and Set according to the requirement. Double check the above then start the testing procedures, confirmed the tested EDM position and the settings are correct then start EDM process.

During the EDM processing, frequently checking the flow of the fluid to ensure no deposition of carbon on the work piece or no undercut was made. Check the dimensions of the work piece with measuring instrument or gauge during EDM process if necessary.

EDM Wire Cutting Section

EDM Wire Cutting Section will handle all the Wire Cutting Works such as Pockets; Inserts; Lifters; Slides; Slots and Holes. All these processes must be conducted according to the drawings and requirements previously released by the Engineering Department and under the monitoring of our strict Quality Control System.

Fitting and Assembling

Fitting and Assembling Section is responsible for the final completion of the mold, all the Cavity & Core Inserts; Slides & Lifters; Parts & Accessories; Screws & Pins and other components must be fitted and assembled by the technicians of this section. They reflect the ability; capability; quality of the mold manufacturing and represent the reputation of the company.

Plastic Mold Manufacturer

Topwell is capable of building 300 to 350 sets of molds per annual, about 25% of them are Bi-material / Double Injection Molds and about 35% are Hot Runner Mold.